Capabilities

Fibre

At Pratibha, every fibre reflects a commitment to responsibility, innovation, and long-term impact. The spinning operations are built around a carefully selected portfolio of sustainable fibres, each chosen for its low environmental footprint and high performance.

- ROC Certified Cotton: Long Staple organic cotton grown using regenerative practices, promoting healthy soils and biodiversity.

- Fairtrade Organic Cotton: Supporting ethical farming and fair wages for rural communities.

- Organic Certified Cotton (NOP/NPOP): Verified organic cotton, ensuring environmentally friendly farming methods.

- Lenzing™ Modal and TENCEL™,

- recycled polyester,

- hemp, linen, and banana fibre blends—balancing performance with planet-positive solutions.

By uniting nature-grown fibres with advanced spinning technologies, we create high-quality materials that reflect our unwavering commitment to a regenerative and responsible future.

To know more about organic cotton initiative, click here.

Yarn Spinning

Cotton Yarns

- Cotton-Based Yarns

- Conventional Cotton

- Organic Cotton (NOP/NPOP Certified)

- Fairtrade Cotton (NOP/NPOP)

- ROC (Regenerative Organic Certified) Cotton

- BCI (Better Cotton Initiative) Cotton

Open-End Yarns

- Conventional

- BCI

- Organic

Specialty & Fancy Yarns

- Grindle

- Injection Slub

- Normal Slub

- Neps

- Mélange

- Eli-Twist

- Micro-Modal

- Hairy Yarns

Vortex Yarns

- Poly-Cotton Vortex

- Tri-Blend Vortex

- Viscose Vortex & Mélange

- Cotton-Viscose Vortex

- Cotton-Modal Vortex

Other Yarn Types

- Ring Yarn

- Compact Yarn

- TFO Yarn

- Slub & Multicount Yarn

- Air Jet Yarn

- Core-Spun Yarn

- Ring-Spun Mélange

Mélange Yarns

- 100% Cotton Mélange

- Poly-Cotton Mélange

- Poly-Viscose Mélange

- Banana Fiber Blends

- Hemp Blends

- Linen Blends

- Wool Blends

- Silk Blends

- Tri-Blend Mélange with Hemp

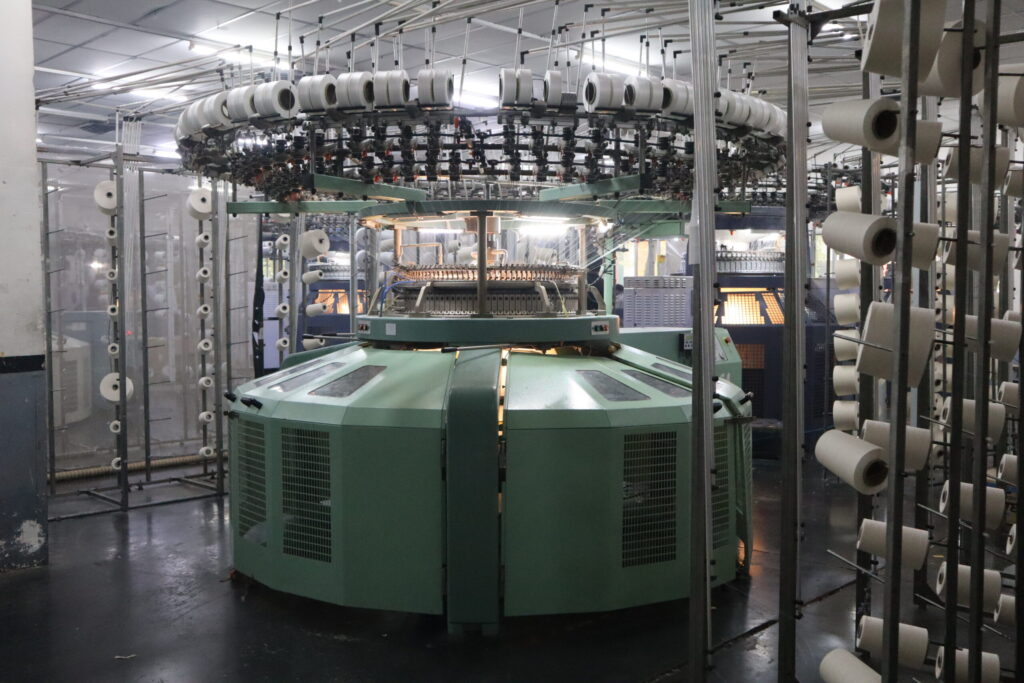

Precision in Circular Knitting

Pratibha’s knitting division is designed for precision, speed, and adaptability. Equipped with high-efficiency circular and flat knitting machines, we make high-quality knitted fabrics annually- serving activewear, loungewear, innerwear, and fashion basics.

Every fabric reflects our commitment to responsible manufacturing, global standards, and performance-driven design. Meet end-use performance criteria while aligning with Pratibha Syntex’s commitment to environmental responsibility and innovation

Core Knits

- Single Jersey

- Rib

- Terry

- Fleece

- PQ Interlock

- Honeycomb

Specialty Knits

- Waffle

- Zigzag Interlock

- Popcorn

- Ber Knit

- Raschel

- Ottoman

- Crepe

Functional Finishes

- Anti-microbial

- Anti-static

- UV resistant

- Stain release

- Wrinkle & fade resistance

- Water repellency

Every fabric reflects our commitment to responsible manufacturing, global standards, and performance-driven design meet end-use performance criteria while aligning with Pratibha Syntex’s commitment to environmental responsibility and innovation

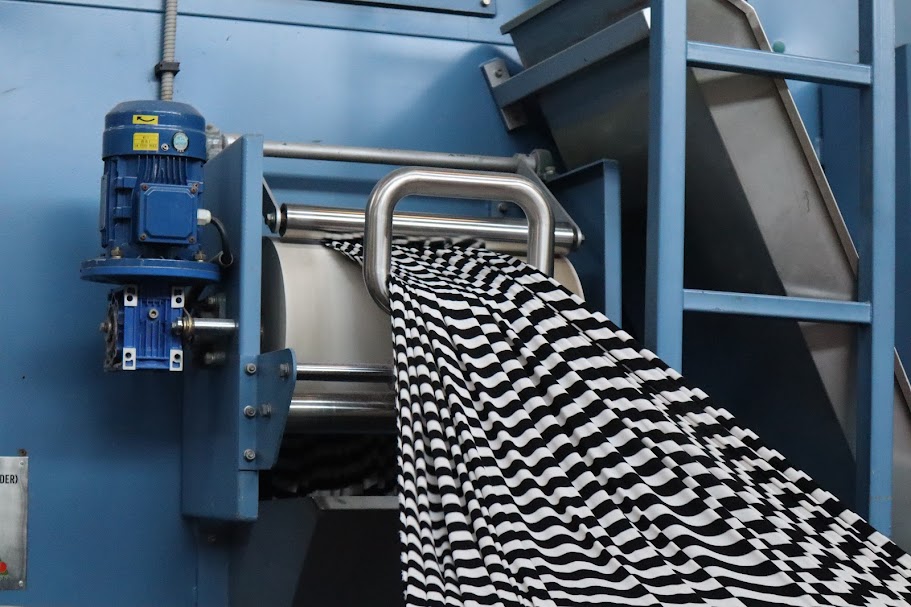

Dyeing

Pratibha integrates advanced soft-flow and open-width dyeing technologies into its operations, designed to reduce environmental impact while maintaining consistent, high-quality output. The use of salt-free, crease-free, low-liquor dyeing processes significantly lowers wastewater generation and energy consumption—aligning with the company’s broader sustainability goals.

- All dyestuffs and chemicals used are GOTS and ZDHC certified , supporting our commitment to responsible chemistry.

- The in-house dyeing lab, accredited to M&S standards, ensures precision in color development and reproducibility.

- Water-efficient operations are supported by real-time automated systems, zero fresh water usage, and advanced wastewater recycling technologies, including STP and RO systems.

Finishing processes such as compacting and tumble drying ensure fabric durability, shrinkage control, and a premium hand feel- all powered by a biomass boiler that reduces carbon emissions.

Printing & Embroidery

- Screen Printing

- Pad Printing

- All-Over Rotary Printing

- Digital Printing

- Computerized Embroidery

Aligned with our environmental goals, all processes use ZDHC-compliant inks and GOTS-certified chemicals, while digital and rotary techniques minimize water and energy consumption. This integrated approach ensures that every design reflects not just visual excellence, but also our commitment to sustainable manufacturing.

Garment Manufacturing

Design Studio

Pratibha’s Design Studio serves as a hub of creativity, innovation, and collaboration—bringing together a skilled team focused on developing collections that align with global trends and evolving consumer needs. The studio specializes in designing casualwear, innerwear, thermals, sleepwear, and fashion apparel for both men and women.

With an emphasis on trend forecasting, market responsiveness, and sustainable design principles, the team creates collections that balance aesthetics, functionality, and environmental responsibility. Each piece is crafted to reflect the identity of partner brands while embedding long-term value through conscious design choices.

Leveraging advanced digital tools such as CLO 3D for virtual sampling, Fermat for garment application, and Frontier for digital fabric libraries, the studio enhances design precision and streamlines the development process—delivering speed, flexibility, and reduced material waste.

Driving Operational Excellence Through Digitization

- IoT-enabled machinery and the Flow Management System (FMS): Real-time monitoring ensures predictive maintenance, consistent quality, and reduced material waste.

- Digital audits and automation: Minimizing manual processes enhances operational discipline, lowers rejection rates, and improves productivity throughout manufacturing.

- Customer dashboards: Live visibility into order status, production timelines, and quality metrics ensures transparent and responsive communication with brand partners.